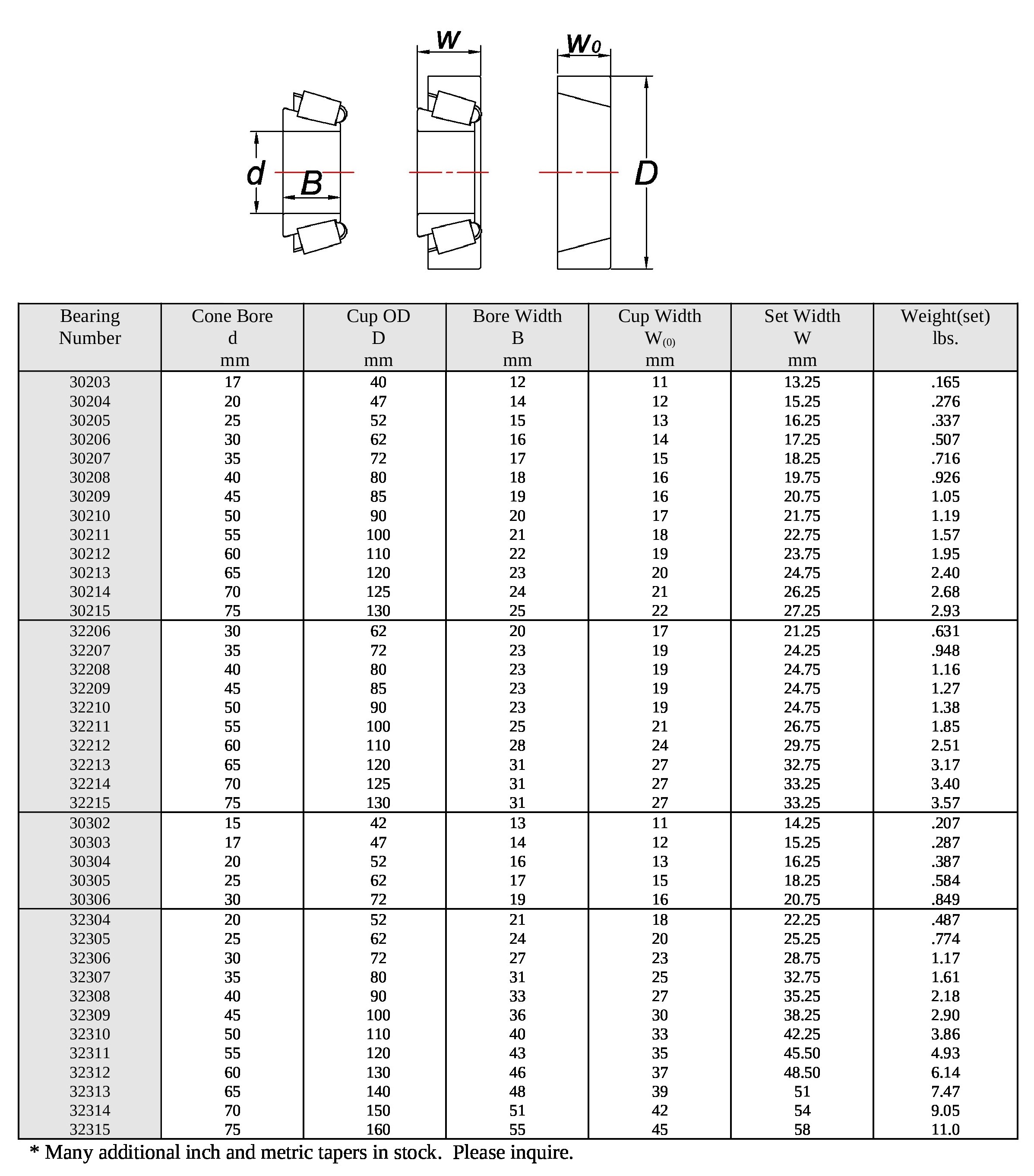

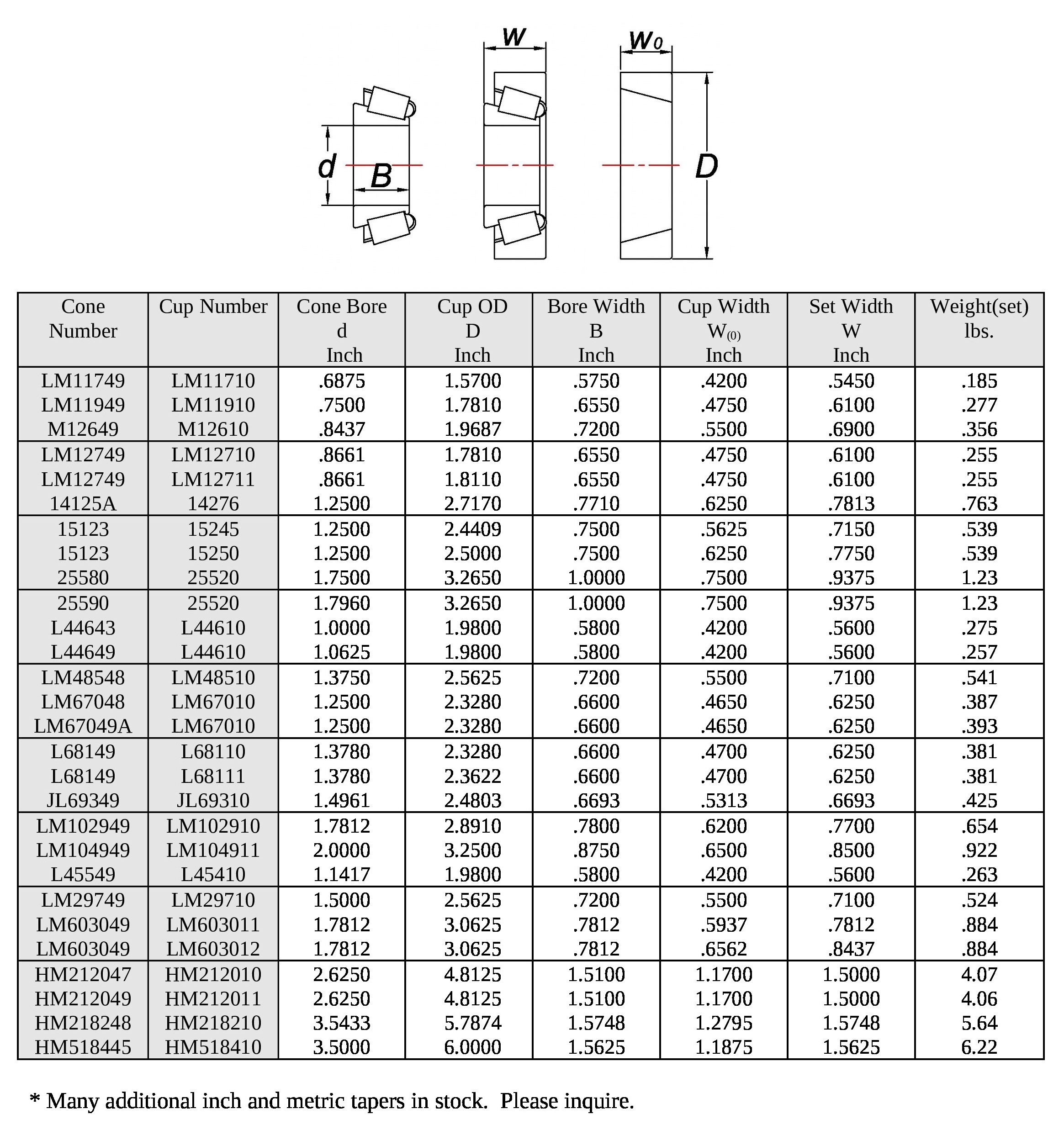

Single row Tapered Roller Bearing

Size

Applications

- Autos

- Rolling mills

- Minings

- Metallurgys

Our Advantages

1.Wear Resistance

The optimized design of drum end and the improvement of flange surface finish are conducive to the formation of lubricating oil film, so as to reduce wear.

2.Reliability

Compared with the traditional straight raceway profile, the design of single row tapered roller bearing optimizes the load on the roller contact surface and reduces the effect of misalignment.